Unlocking Efficiency: The Proven Advantages of Advanced Drilling Machines in Modern Manufacturing

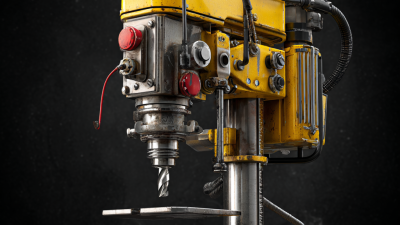

In the modern manufacturing landscape, the adoption of advanced drilling machines has become a pivotal factor in enhancing operational efficiency and productivity. According to a report by MarketsandMarkets, the global drilling machine market is anticipated to reach USD 9.15 billion by 2025, growing at a CAGR of 4.6% from 2020 to 2025. This growth is driven by the increasing demand for precision in component manufacturing across various industries, including aerospace, automotive, and electronics. Advanced drilling machines incorporate cutting-edge technologies such as CNC automation and intelligent software integration, enabling manufacturers to achieve higher accuracy, reduced waste, and accelerated production times. As companies strive to remain competitive, understanding and leveraging the advantages of these innovative tools is essential for unlocking new levels of efficiency in manufacturing processes.

Revolutionizing Precision: How Advanced Drilling Machines Enhance Manufacturing Accuracy

In the rapidly evolving landscape of modern manufacturing, precision has emerged as a defining characteristic of successful operations. Advanced drilling machines are at the forefront of this revolution, incorporating cutting-edge technology to significantly enhance manufacturing accuracy. These machines utilize advanced algorithms and real-time data analysis to optimize drilling processes, reducing human error and ensuring consistent results across production runs.

Moreover, the integration of CNC (Computer Numerical Control) technology allows for unparalleled precision in drilling applications. Manufacturers can achieve intricate designs and tight tolerances that were once deemed impossible. The ability to program these machines with exact specifications not only minimizes waste but also boosts production efficiency, allowing manufacturers to meet rising demands without sacrificing quality.

As industries continue to innovate, the role of advanced drilling machines in enhancing operational accuracy is becoming increasingly indispensable.

Maximizing Output: The Impact of High-Speed Drilling Technology on Production Rates

High-speed drilling technology is revolutionizing production rates across various industries, enabling manufacturers to achieve unprecedented levels of efficiency. According to a report by MarketsandMarkets, the global market for advanced drilling machinery is expected to grow from $6.5 billion in 2022 to $9.1 billion by 2027, reflecting a compound annual growth rate (CAGR) of 7.5%. This surge is largely attributable to innovations in drill designs and materials that facilitate faster penetration rates and reduce cycle times.

In practical terms, manufacturers employing high-speed drilling machines have reported significant improvements in their output. For instance, a study conducted by the International Journal of Advanced Manufacturing Technology revealed that the integration of high-speed drills can increase production rates by up to 40%, while simultaneously enhancing dimensional accuracy. These advancements not only streamline operations but also reduce material waste, which is crucial in minimizing overall operational costs. As industries continue to prioritize efficiency, the impact of high-speed drilling technology will only become more pronounced, shaping the future of manufacturing processes.

Cost Efficiency: The Financial Benefits of Integrating Advanced Drilling Machines

In the ever-evolving landscape of modern manufacturing, the integration of advanced drilling machines has become a pivotal factor in achieving cost efficiency. According to a report by Market Research Future, the global drilling machine market is projected to grow at a CAGR of 6.2% from 2021 to 2027. This surge highlights manufacturers' increasing recognition of the financial advantages these machines offer, specifically in labor savings and reduced material waste. Advanced drilling machines streamline operations by automating processes, which significantly reduces manual labor costs and minimizes the error rates that often lead to expensive reworks.

Additionally, the use of advanced drilling technologies enables manufacturers to optimize their material usage. A study by the Manufacturing Institute found that companies employing precision drilling techniques reported up to 25% reductions in material waste. This not only lowers raw material costs but also contributes to more sustainable manufacturing practices. Implementing these machines results in quicker production times and enhanced product quality, further translating to improved profitability for organizations. As technology continues to advance, the focus on integrating such efficient machinery will likely play a crucial role in reducing operational costs while driving competitive advantage in the marketplace.

Cost Efficiency of Advanced Drilling Machines in Modern Manufacturing

This chart illustrates the cost efficiency of integrating advanced drilling machines into modern manufacturing processes. The categories show the comparison between initial investment, operation costs, maintenance costs, and expected production output, highlighting the financial benefits these machines offer over traditional methods.

Sustainability in Manufacturing: Eco-Friendly Innovations in Drilling Technology

In the realm of modern manufacturing, sustainability is no longer just a buzzword; it's a core component driving innovation. The shift towards eco-friendly practices has seen drilling technology evolve remarkably. According to a report from the International Energy Agency, the industrial sector accounts for approximately 30% of global energy consumption. By integrating advanced drilling machines equipped with energy-efficient technologies, manufacturers can significantly reduce their carbon footprint and enhance operational efficiency. These machines leverage smart technology to optimize energy usage, potentially decreasing energy costs by 15-20%.

Moreover, the adoption of sustainable materials in drilling processes is gaining momentum. A study from the Manufacturing Institute notes that materials such as biodegradable composites and recycled metals are increasingly being utilized, demonstrating a reduction in waste and environmental impact. These innovations not only align with regulatory standards but also appeal to a growing consumer base that prioritizes eco-conscious products. As companies invest in advanced drilling technologies, they not only improve their production capabilities but also contribute positively to the planet, showcasing a win-win for both the industry and the environment.

Unlocking Efficiency: The Proven Advantages of Advanced Drilling Machines in Modern Manufacturing

| Feature | Advantage | Sustainability Factor | Efficiency Improvement (%) |

|---|---|---|---|

| High Precision | Reduces waste and rework | Minimized material usage | 25% |

| Automated Control | Increases production speed | Energy-efficient operations | 35% |

| Advanced Materials | Longer machine life | Reduced resource extraction | 15% |

| Reduced Noise Emissions | Improves workplace safety | Lower environmental impact | N/A |

| Smart Analytics | Better maintenance scheduling | Optimizes resource usage | 20% |

Real-World Applications: Showcasing Successful Implementations of Advanced Drilling Machines

In the realm of modern manufacturing, advanced drilling machines have been pivotal in enhancing productivity and precision. One notable example of successful implementation can be observed in the automotive industry, where companies have integrated CNC drilling systems to streamline the production of complex components. These machines not only reduce cycle times but also ensure unparalleled accuracy, which is crucial for maintaining the high standards of safety and performance that consumers expect.

Another compelling case is found in the aerospace sector, where advanced drilling technology is used for lightweight materials such as carbon fiber composites. By utilizing specialized drilling rigs, manufacturers can create intricate designs while minimizing waste and maximizing structural integrity. This has led to significant improvements in aircraft performance and fuel efficiency. These real-world applications highlight the transformative impact of advanced drilling machines, demonstrating their essential role in driving efficiency and innovation across various manufacturing domains.

Related Posts

-

What is the Best Drilling Machine? Exploring Features, Efficiency, and Global Trends in 2023

-

Innovative Alternatives to the Best Drilling Machine for Your Project Needs

-

China's Premier Factory Delivering Unmatched Excellence in Best Cnc Laser Products Worldwide

-

Ultimate Guide to Mastering the Best Cnc Tube Cutting Machine Techniques

-

Driving Success with Plate Laser Cutting Machine at the Record Breaking Canton Fair 2025

-

2025 Trends in Precision Manufacturing: Harnessing the Power of the Best Industrial Laser Cutting Machines