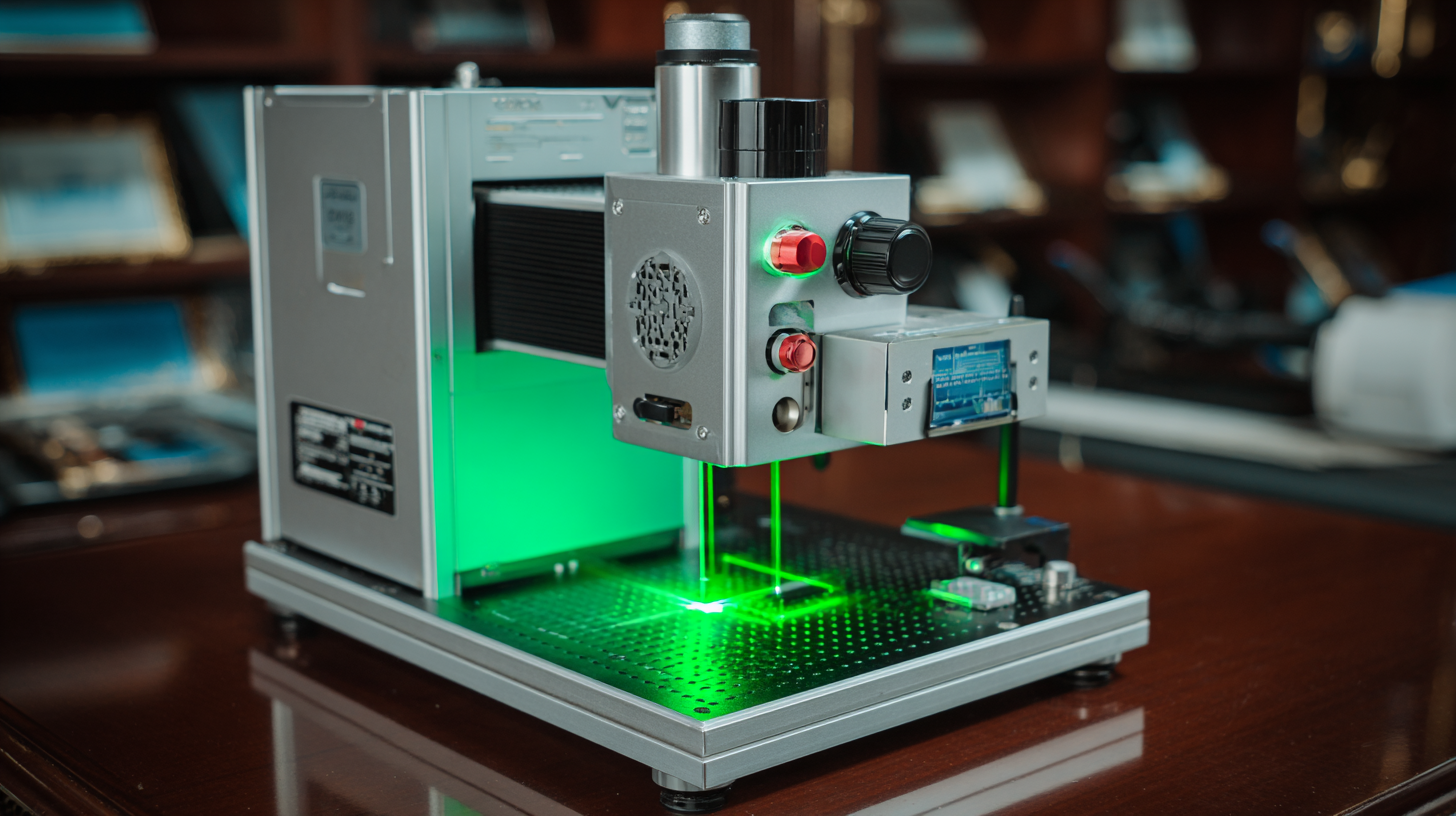

Exploring After Sales Service Benefits and Maintenance Costs in the Future of Best Small Laser Cutting Machines

In the rapidly advancing world of manufacturing, the emergence of Small Laser Cutting Machines has revolutionized various industries, offering precision and versatility for intricate tasks. As businesses continue to adopt these sophisticated tools, understanding the after-sales service benefits and maintenance costs becomes paramount for ensuring long-term operational efficiency. This blog will explore key industry applications of Small Laser Cutting Machines and highlight potential problems that users may encounter. By delving into the advantages of robust after-sales support and the financial implications of maintenance, we aim to provide insights that help stakeholders make informed decisions about their investments in laser cutting technology. Ultimately, the future of laser cutting hinges not only on the machines themselves but also on the comprehensive support systems that empower businesses to maximize their performance.

Benefits of After Sales Service for Small Laser Cutting Machines

In the competitive landscape of small laser cutting machines, after-sales service plays a pivotal role in enhancing customer satisfaction and operational efficiency. A recent industry report by Market Research Future indicates that companies with robust after-sales support can see a 25% increase in customer loyalty. This loyalty translates into repeat business and referrals, crucial for any company aiming to thrive in the laser cutting sector. Having access to expert support ensures that users can maximize their machine's potential, reducing downtime and increasing productivity.

**Tip:** Regularly schedule maintenance checks with service providers to prevent costly repairs and ensure that your machine operates at peak efficiency. This proactive approach not only extends the lifespan of the laser cutting machines but also minimizes unexpected disruptions in production.

Moreover, while the initial investment in small laser cutting machines can be significant, the cost of maintaining them is often influenced by the quality of after-sales services offered. According to a study by Statista, businesses that utilize effective after-sales services can reduce overall maintenance costs by up to 15%. Investing in a machine supported by excellent service options can result in substantial long-term savings.

**Tip:** Choose a supplier who offers comprehensive training and ongoing support for their machines. This investment ensures that your team is well-equipped to handle operations and troubleshooting, further decreasing the likelihood of costly mistakes.

Understanding Maintenance Costs: Key Factors to Consider

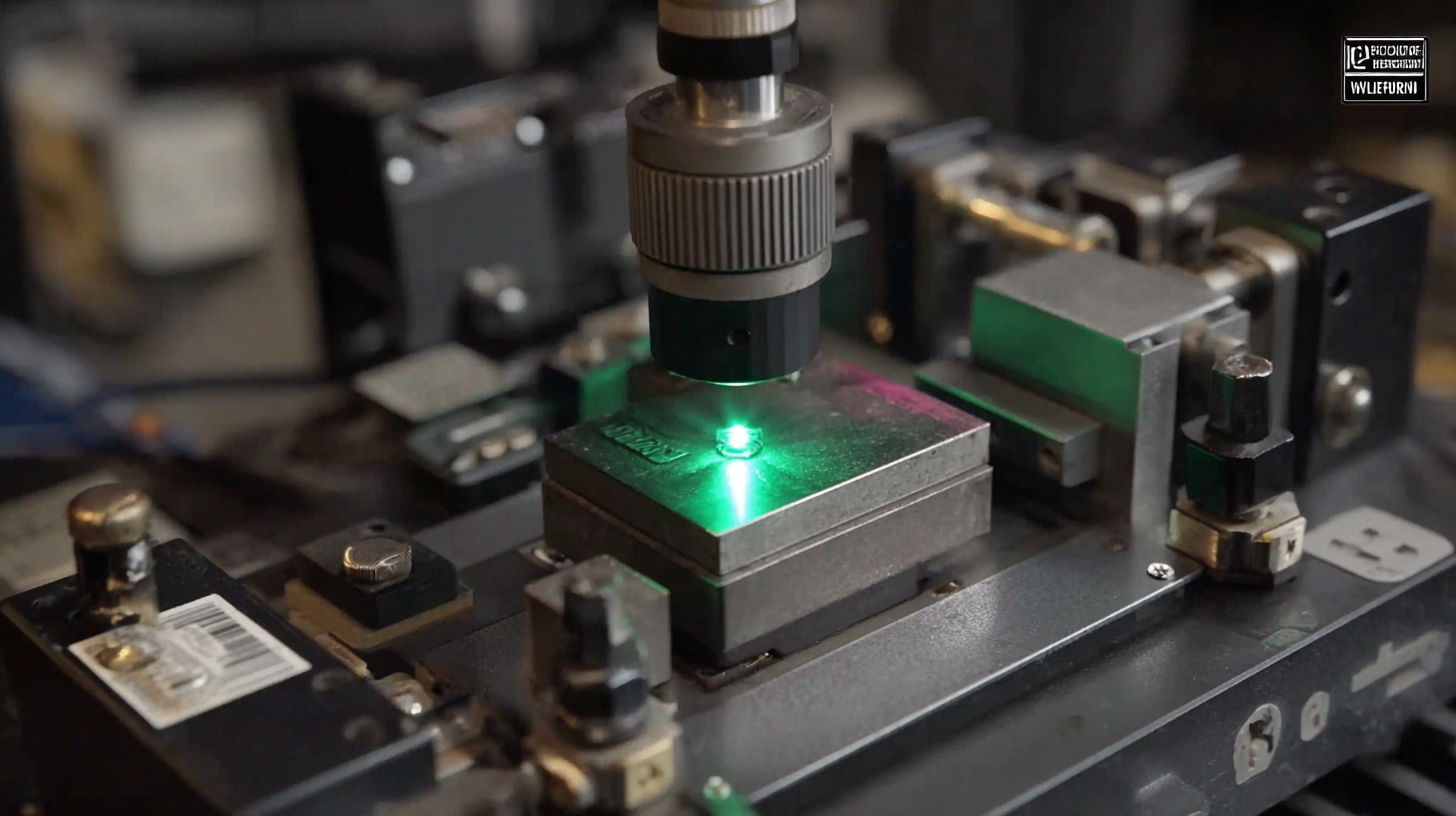

When investing in small laser cutting machines, understanding maintenance costs is crucial for long-term operational efficiency. Several key factors can influence these costs, including the machine's design, the frequency of use, and the types of materials being processed. Regular maintenance not only enhances performance but also extends the lifespan of the machine, ultimately saving money in replacement costs.

Tips: Keep a detailed maintenance log to track repairs and servicing schedules. This proactive approach can help identify potential issues before they escalate, ensuring that your machine operates at peak performance. Additionally, consider investing in training for staff to operate the machinery efficiently and identify maintenance needs promptly.

Moreover, the choice of components significantly impacts maintenance expenses. Higher-quality parts may have a higher upfront cost, but they often provide greater reliability and reduce overall maintenance needs. By evaluating the total cost of ownership, businesses can make informed decisions that balance initial investments with future savings.

Tips: Always source replacement parts from reputable suppliers to guarantee compatibility and quality. This not only aids in maintaining optimal performance but can also prevent unexpected breakdowns that lead to costly repairs.

Comparative Analysis of Different Laser Cutting Machines

The landscape of laser cutting technology is evolving, driven by innovations that cater specifically to the needs of small-to-medium enterprises. A comparative analysis of various laser cutting machines reveals significant differences not only in performance but also in after-sales service and maintenance costs. According to a report by MarketsandMarkets, the global laser cutting machine market is projected to reach $5.67 billion by 2026, growing at a CAGR of 6.26% from 2021. This steady growth indicates a rising adoption of modern laser technologies, with manufacturers increasingly focusing on providing machines that offer not only precision but also user-friendly maintenance solutions.

When examining various models, the after-sales service provided by manufacturers can greatly influence the total cost of ownership. For instance, some small laser cutting machines feature modular designs that simplify maintenance, reducing downtime. A study from the Laser Institute of America indicates that machines with comprehensive service agreements can lead to a 20-30% reduction in unplanned maintenance costs. The efficiency of after-sales support correlates directly with operational productivity, reinforcing the importance of evaluating service offerings alongside initial pricing. Thus, when choosing a laser cutting machine, it's essential to consider both performance metrics and the long-term implications of maintenance and support services.

Comparative Analysis of After Sales Service Benefits and Maintenance Costs for Small Laser Cutting Machines

How to Choose the Right Small Laser Cutting Machine for Your Needs

Choosing the right small laser cutting machine is a vital decision for any business aiming for precision and efficiency. First, assess your specific requirements based on the materials you intend to cut, the thickness of the materials, and the desired application. For instance, if you plan to work primarily with wood or acrylic, a CO2 laser cutter may be suitable. Conversely, for metal cutting, a fiber laser could be more appropriate. Understanding these nuances helps narrow down options and ensures that the machine you select will meet your operational demands.

Another critical factor to consider is the machine's ease of use and maintenance. Look for models that provide user-friendly interfaces and excellent customer support, particularly in terms of after-sales service. Regular maintenance is essential for ensuring longevity and performance, so invest in a machine that offers clear guidelines and accessible components for upkeep. By focusing on these aspects, you can make an informed choice that not only fits your current needs but also positions you for future growth in your cutting projects.

Future Trends in Laser Cutting Technology and Their Impact on After Sales Services

As the demand for precision and efficiency in manufacturing increases, the landscape of laser cutting technology is evolving rapidly. Future trends point towards advancements such as improved automation, enhanced software capabilities, and the integration of artificial intelligence. These innovations not only elevate the performance of small laser cutting machines but also directly influence after-sales services, which are becoming increasingly vital for customer satisfaction and retention. Companies that leverage real-time monitoring and predictive maintenance will be better positioned to anticipate service needs, ultimately reducing downtime and operational costs for users.

Moreover, the transition towards more sophisticated laser cutting systems demands a reevaluation of maintenance strategies. The trend of modular design, where components can be easily upgraded, offers significant advantages. This adaptability ensures that machines remain at the forefront of technology without the need for complete overhauls. Manufacturers are now focusing on providing comprehensive support packages that include training, remote diagnostics, and proactive maintenance. This shift not only enhances the longevity of equipment but also fosters a strong partnership between manufacturers and end-users, paving the way for a more service-oriented approach in the laser cutting industry.