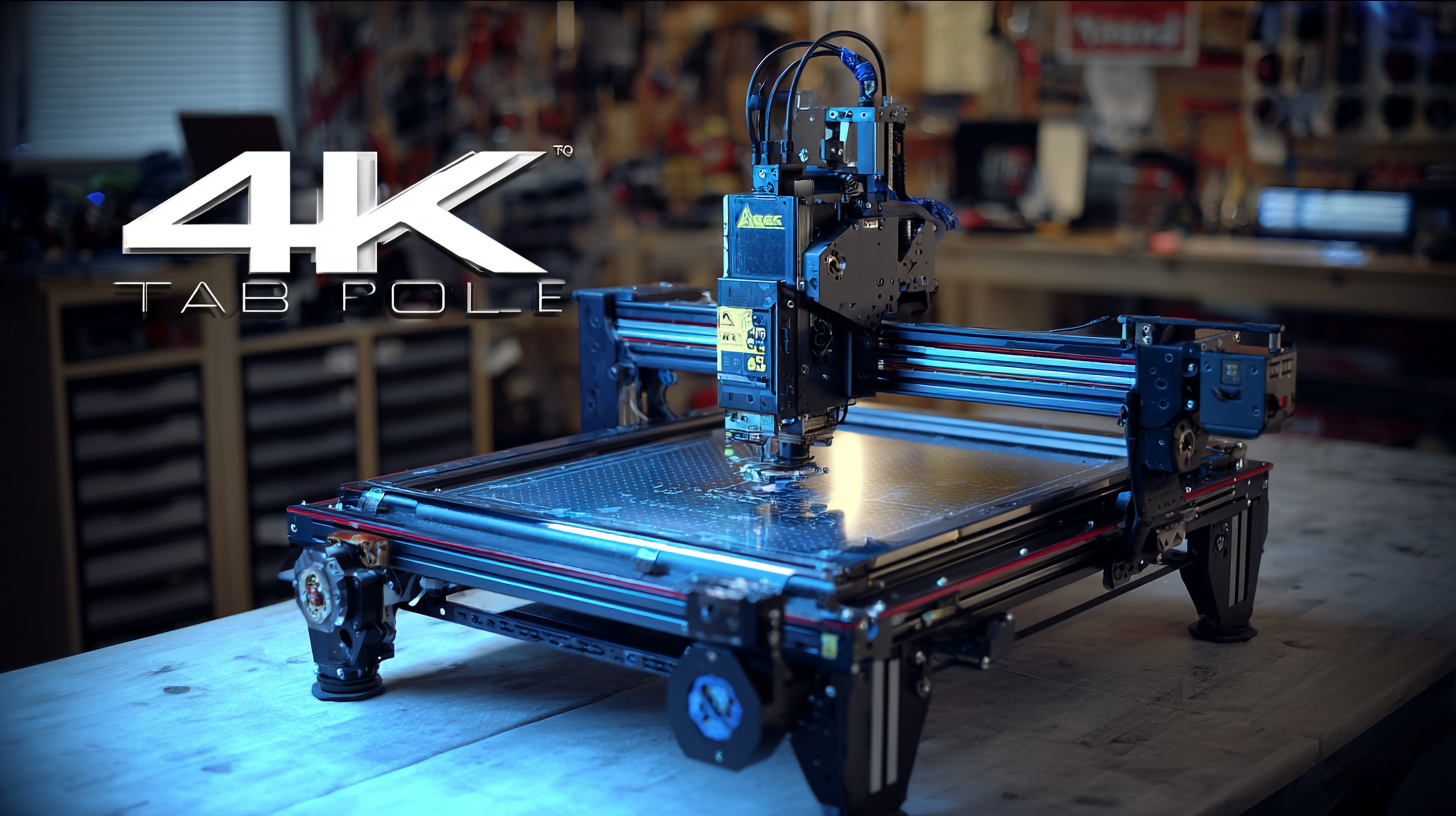

7 Reasons Why the Best Small Plasma Table is a Game Changer for Your Business

In an era where precision and efficiency dictate competitiveness in the manufacturing industry, investing in the right equipment is paramount. The emergence of advanced technologies has reshaped traditional fabrication processes, with the Small Plasma Table leading the way for small to medium-sized businesses. According to a report by MarketsandMarkets, the global plasma cutting market is projected to reach $4.9 billion by 2026, highlighting the growing importance of efficient cutting systems. A Small Plasma Table not only offers enhanced cutting precision but also saves valuable production time and resources, making it a game changer for many businesses. With the ability to handle diverse materials and complex designs, this technology empowers enterprises to streamline operations and improve product quality, ultimately amplifying their competitive edge in a rapidly evolving marketplace. Embracing this innovation can lead to more efficient workflows and increased profitability, making a compelling case for businesses to consider upgrading their equipment.

Revolutionizing Metal Fabrication: The Role of Small Plasma Tables in 2025

In 2025, small plasma tables are poised to revolutionize the metal fabrication industry, much like how innovative technologies are transforming fields such as orthopedic surgery. With the global CNC plasma cutting machines market projected to grow at a CAGR of over 5.1%, reaching significant valuations by 2034, it’s clear that the demand for efficient and precise cutting solutions is on the rise. Small plasma tables offer unparalleled flexibility and speed, making them essential tools for businesses looking to stay competitive in an evolving landscape.

Tips for maximizing the benefits of small plasma tables include investing in high-quality software that integrates seamlessly with your design processes. This not only streamlines operations but also enhances the precision of cuts, reducing material waste. Additionally, regular maintenance and upgrades to the machine can significantly improve performance and longevity.

As we advance, the application of small plasma tables will likely expand beyond traditional manufacturing. Their potential for customization makes them ideal for various industries seeking personalized solutions. Embracing this technology will not only enhance production capabilities but also position businesses at the forefront of innovation in metal fabrication.

Key Advantages of High-Precision Cutting for Small Businesses in the New Tech Era

In today's rapidly evolving tech landscape, small businesses face the significant challenge of maintaining efficiency and precision. High-precision cutting technology, particularly in small plasma tables, offers key advantages that can transform operations. With the ability to perform intricate cuts quickly and accurately, small plasma tables can streamline production processes, allowing businesses to deliver high-quality products while reducing waste.

One tip for leveraging high-precision cutting is to invest time in proper training for your team. Familiarizing staff with the functionality and capabilities of the plasma table ensures they can maximize its potential, enhancing overall productivity. Moreover, take advantage of software integration that allows for seamless design and programming. This not only reduces setup time but also minimizes errors, ultimately leading to better customer satisfaction.

Additionally, it’s essential to establish a regular maintenance routine for your plasma cutting machine. Routine inspections and servicing can prevent downtime caused by equipment malfunction, ensuring that your business remains on schedule. By focusing on these aspects, small businesses can significantly improve their manufacturing efficiency and output quality in this new tech era.

Impact of High-Precision Cutting on Small Businesses

Cost Efficiency and Productivity Boost: How Small Plasma Tables Transform Operations

Small plasma tables are revolutionizing the manufacturing industry, primarily in terms of cost efficiency and productivity. With the ability to cut through various materials such as metal and plastic with precision, these machines can significantly reduce waste and operational expenses. According to a report by IBISWorld, the sheet metal fabrication industry alone generates over $39 billion in revenue annually, showcasing a growing market that benefits from advanced technologies. These tables not only streamline production processes but also minimize downtime, allowing businesses to react quickly to customer demands.

When using a small plasma table, it's essential to consider the setup process for maximum efficiency. One tip is to optimize your material layout on the cutting table to reduce scrap and improve overall yield. By planning cuts meticulously, businesses can ensure they make the most out of each sheet, leading to reduced material costs. Additionally, investing in training for your team can pay dividends; knowledgeable operators can better leverage the capabilities of the plasma table, resulting in faster turnaround times and higher quality outputs.

Moreover, small plasma tables often incorporate advanced software that enables quick adjustments to design plans, enhancing flexibility in production. Data from the Association for Manufacturing Technology indicates that companies utilizing such technology experience productivity boosts of up to 25%. This adaptability not only affects current projects but also positions businesses competitively in the marketplace, allowing them to quickly adapt to changes in client specifications without significant delays.

7 Reasons Why the Best Small Plasma Table is a Game Changer for Your Business

| Reason | Description | Impact on Business |

|---|---|---|

| 1. Cost Efficiency | Lower operational costs due to reduced material waste and efficient energy consumption. | Increased profit margins. |

| 2. Enhanced Precision | High-definition cutting capabilities that ensure accuracy in designs. | Minimized errors and reworks. |

| 3. Increased Productivity | Faster cutting speeds compared to traditional methods. | Higher output per hour. |

| 4. Versatile Applications | Adaptable for various materials including metal, plastic, and foam. | Ability to serve multiple markets. |

| 5. Space Saving | Compact design suitable for small workshops. | Maximized workspace utilization. |

| 6. User-Friendly Technology | Intuitive software and remote control options. | Reduced training time and easier operation. |

| 7. Lower Maintenance Costs | Durable technology that requires less frequent servicing. | Long-term savings on maintenance. |

Exploring the Integration of Automation and Smart Technology in Plasma Cutting

The integration of automation and smart technology in plasma cutting represents a significant leap forward for small businesses looking to enhance efficiency and precision. With the best small plasma tables equipped with advanced software, operators can streamline their design processes, leading to quicker turnaround times and reduced material waste. This shift not only saves time but also promotes a sustainable approach to manufacturing.

To maximize the benefits of smart technology, consider regularly updating your software to ensure you are utilizing the latest features. Additionally, investing in a plasma table that offers remote monitoring can greatly improve your workflow. Being able to oversee operations from anywhere allows for immediate adjustments and minimizes downtime caused by technical issues.

Furthermore, integrating automation into your plasma cutting processes can significantly enhance productivity. Utilize features such as automatic height sensing and adaptive pierce technology to improve cut quality and consistency. This will not only elevate your output but also boost customer satisfaction, positioning your business as a leader in precision cutting.

Future Trends: Enhancements in Plasma Table Features to Watch for in 2025

As we approach 2025, the landscape of plasma table technology is set to revolutionize industries ranging from metal fabrication to artistic design. One of the most exciting enhancements on the horizon is the incorporation of artificial intelligence in plasma cutting operations. AI-powered plasma tables will not only optimize cutting speeds and precision but also minimize waste by analyzing materials and suggesting the best cutting paths. This advancement will empower small businesses to maximize efficiency, allowing them to compete on a larger scale while maintaining cost-effectiveness.

Another trend to watch for is increased connectivity through IoT (Internet of Things) integration. Future plasma tables will likely feature smart sensors and remote monitoring capabilities, enabling operators to track performance metrics from their smartphones or computers. This level of connectivity will facilitate proactive maintenance, reducing downtime and ensuring continuous production. Moreover, real-time data analytics will offer insights that help businesses streamline operations, improve workflows, and make informed decisions, further elevating the role of plasma technology in modern manufacturing processes.