Innovative Applications of Cnc Tube Cutting Machine in Various Industries

The CNC Tube Cutting Machine has emerged as a pivotal technology across various industries, redefining fabrication processes and enhancing productivity levels. According to a report by MarketsandMarkets, the global CNC machine market is projected to grow from USD 68.9 billion in 2020 to USD 102.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.4%. This growth is fueled by the increasing demand for precision engineering and efficient material processing in sectors such as automotive, aerospace, and manufacturing.

The implementation of CNC tube cutting technology not only streamlines operations but also significantly reduces waste and costs, improving overall operational efficiency. As industries strive for automation and precision, the benefits of CNC Tube Cutting Machines become increasingly evident, paving the way for innovative applications that meet the evolving needs of modern production environments.

Revolutionizing Manufacturing: The Role of CNC Tube Cutting Machines

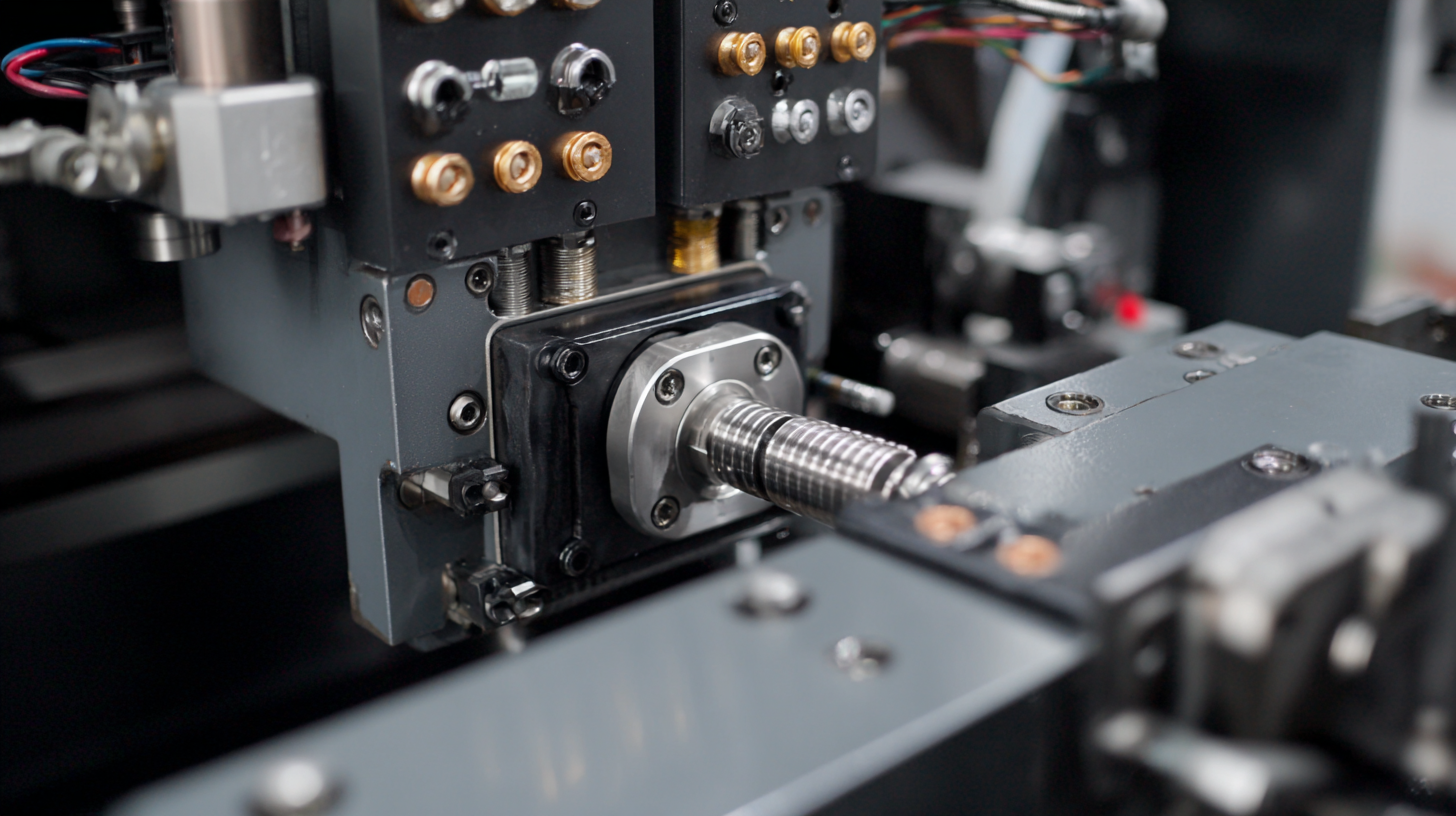

CNC tube cutting machines are revolutionizing the manufacturing landscape across various industries by delivering precision, efficiency, and flexibility. These advanced machines utilize computer numerical control technology to ensure that each cut is exact, minimizing waste and maximizing productivity. The ability to customize cuts based on specific requirements allows manufacturers to adapt quickly to market demands, leading to a more streamlined production process.

CNC tube cutting machines are revolutionizing the manufacturing landscape across various industries by delivering precision, efficiency, and flexibility. These advanced machines utilize computer numerical control technology to ensure that each cut is exact, minimizing waste and maximizing productivity. The ability to customize cuts based on specific requirements allows manufacturers to adapt quickly to market demands, leading to a more streamlined production process.

Tip: When considering the implementation of a CNC tube cutting machine, it’s crucial to assess the machine's compatibility with your existing manufacturing workflow. Invest time in training your team to fully leverage the capabilities of the technology, ensuring optimal operation and reducing the learning curve.

The versatility of CNC tube cutting machines extends beyond traditional applications; they are increasingly being used in industries such as automotive, construction, and aerospace. This adaptability allows manufacturers to create complex geometries and intricate designs with ease, leading to innovations in product development.

Tip: Regular maintenance and calibration of CNC tube cutting machines are key to sustaining their performance and longevity. Establish a routine maintenance schedule and keep an eye on the machining capabilities to avoid potential downtimes and ensure consistent output quality.

Customization at Its Best: Tailoring Solutions Across Industries

The CNC tube cutting machine has emerged as a transformative tool across multiple industries, offering unprecedented levels of customization that cater to specific project requirements. From automotive to aerospace, this technology allows manufacturers to tailor their cutting processes precisely to the dimensions and materials required by each application. With the ability to program intricate designs and precise cuts, businesses can optimize production efficiency and reduce waste, ultimately leading to enhanced profitability.

In industries such as construction, where unique shapes and sizes are often essential, the CNC tube cutting machine excels in delivering bespoke solutions. Its versatility enables companies to produce components that fit seamlessly into diverse projects, from intricate structural frameworks to specialized piping systems. As industries continue to evolve towards greater customization, the role of CNC technology will only become more significant, enabling unprecedented adaptability and creativity in manufacturing processes. This move towards personalized production not only meets the demands of a more discerning market but also fosters innovation across various sectors.

Innovative Applications of CNC Tube Cutting Machines Across Industries

Enhancing Precision: Impact of CNC Technology on Tube Cutting

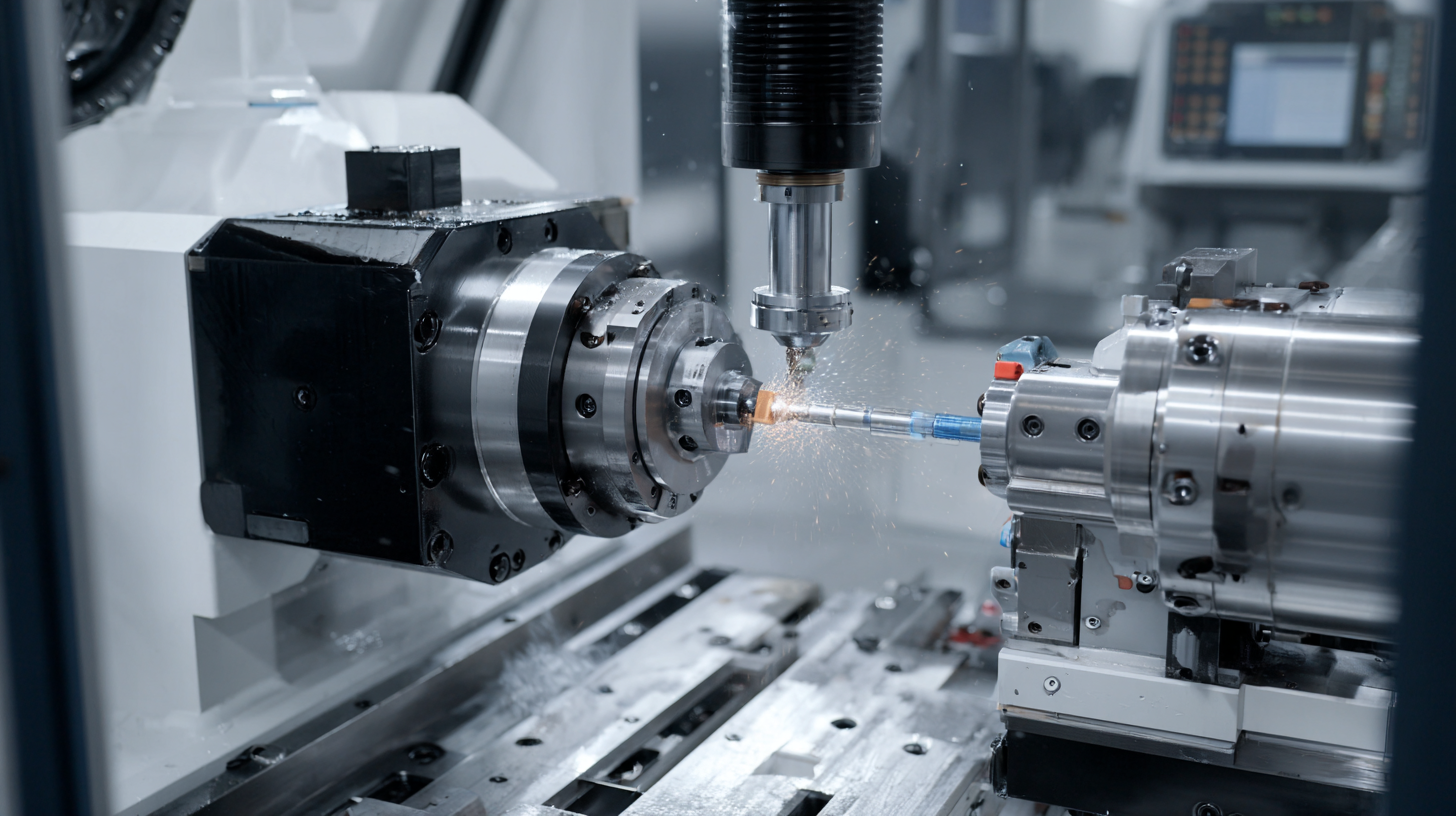

CNC technology has revolutionized tube cutting processes across various industries, elevating precision and efficiency to unprecedented levels. By leveraging computer numerical control, manufacturers can achieve intricate cuts with minimal human intervention. This advancement ensures that dimensions remain consistent, reducing the likelihood of errors typically associated with manual cutting methods. As a result, industries such as automotive, aerospace, and construction benefit from enhanced quality in their final products.

Moreover, the versatility of CNC tube cutting machines allows for the creation of complex geometries that were once deemed unattainable. This capability not only streamlines production but also opens up new avenues for design innovation. For example, in the aerospace sector, precise tube cutting contributes to lighter and more aerodynamic components, enhancing fuel efficiency. The adaptability of CNC technology facilitates easy programming for various materials and shapes, empowering engineers to push the boundaries of creativity while maintaining the required precision. Overall, the impact of CNC technology on tube cutting is a testament to how industries can thrive through innovation.

Sustainability in Action: Eco-friendly Innovations in Tube Cutting

The growing emphasis on sustainability has inspired transformative innovations across various sectors, including the application of CNC tube cutting machines. As industries pivot towards eco-friendly practices, these machines are not just enhancing precision and efficiency but are also integral to the development of sustainable solutions. For instance, recent surveys indicate that around 90% of consumers prefer brands that prioritize sustainable packaging, driving companies to focus on minimizing their environmental footprint through innovative tube designs and materials.

In the realm of engineering and manufacturing, sustainable practices are rapidly becoming a competitive advantage. Advanced CNC tube cutting technologies facilitate the production of lightweight and recyclable materials, significantly reducing waste. Additionally, these innovations align with wider efforts to lower carbon emissions, as seen in marine propulsion systems that utilize biofuels designed to minimize black carbon output. The integration of sustainable aspects into manufacturing processes can lead to increased consumer trust and loyalty, particularly among younger generations who are more conscious of their environmental impact. This reflects a palpable shift towards sustainability, marking a promising trend in various industries, including packaging, automotive, and construction.

Innovative Applications of Cnc Tube Cutting Machine in Various Industries - Sustainability in Action: Eco-friendly Innovations in Tube Cutting

| Industry | Application | Sustainability Benefits | Innovation Type |

|---|---|---|---|

| Automotive | Exhaust Systems | Reduced waste through precise cuts | Laser Cutting |

| Construction | Structural Tubing | Material conservation and efficiency | Plasma Cutting |

| Aerospace | Fuel Lines | Lightweighting and energy efficiency | Water Jet Cutting |

| Furniture | Decorative Tubes | Sustainable sourcing of materials | CNC Machining |

| Energy | Piping Systems | Reduction in production emissions | Custom Cutting Solutions |

Future Trends: What’s Next for CNC Tube Cutting Machines?

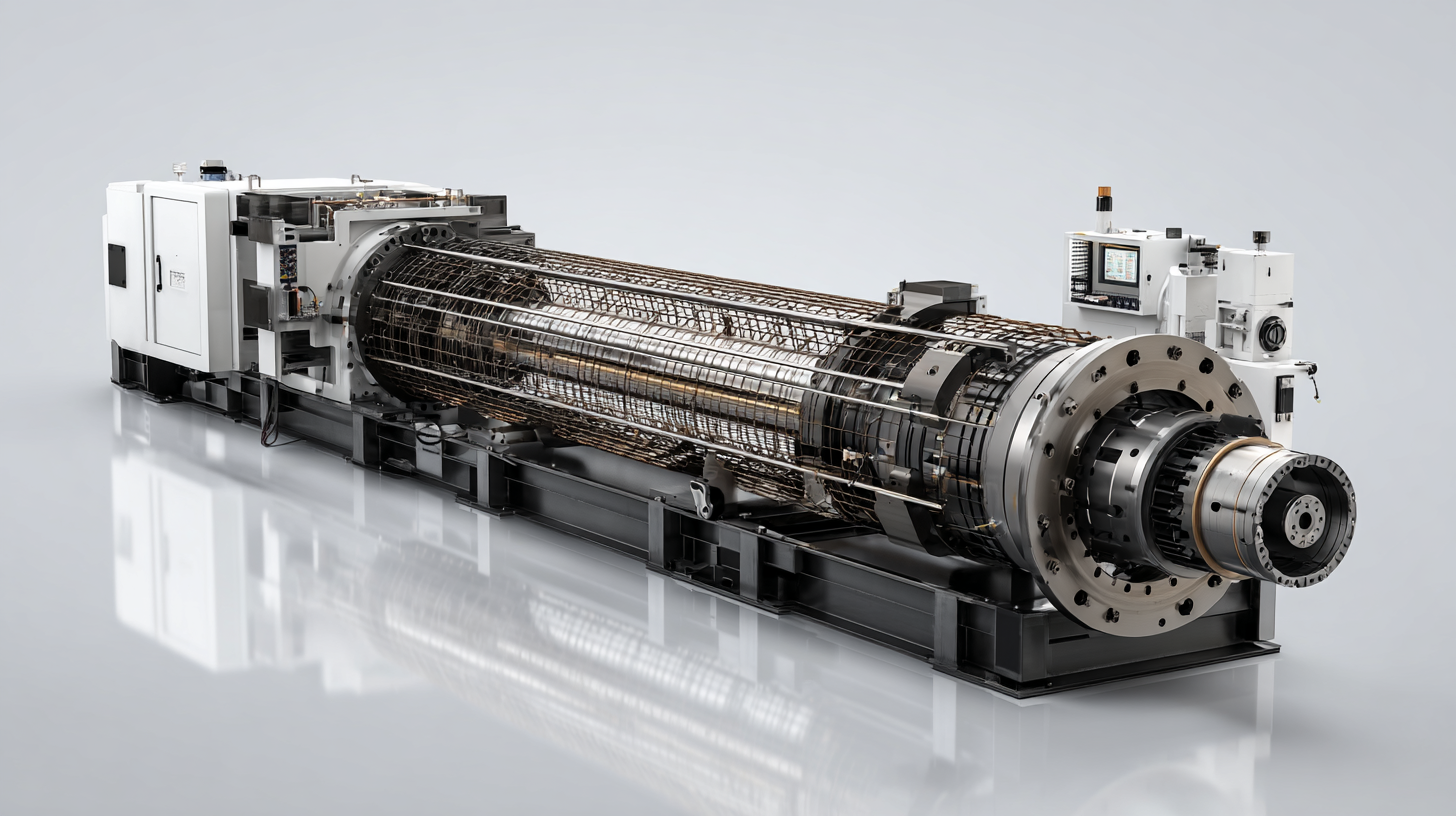

The future of CNC tube cutting machines is poised for exciting advancements, influenced by the escalating demand for precision and efficiency in various industries. As manufacturing environments evolve, the integration of smart technologies and automation is becoming increasingly prevalent. This trend is exemplified by the recent opening of new smart factories, which showcase sophisticated manufacturing capabilities and emphasize local production efficiency. Such developments are indicative of a broader movement towards more intelligent, responsive production systems that can adapt to the specific needs of a diverse range of applications.

Moreover, the CNC pipe bender market is predicted to grow significantly, reflecting a shift towards automated solutions that enhance productivity and reduce error margins. With the increasing implementation of CNC technology, industries are poised to benefit from enhanced quality control and faster turnaround times. The rise of laser tube cutting machines highlights this shift, as they offer cleaner and more accurate cutting methods, aligning perfectly with modern manufacturing demands.

As these trends continue to evolve, we anticipate a future where CNC tube cutting machines not only streamline production but also drive innovation across multiple sectors, from aerospace to automotive.