5 Compelling Reasons to Invest in a Cnc Plasma Cutter for Your Business

In today's competitive manufacturing landscape, investing in advanced technology is not just an option but a necessity for businesses aiming to enhance efficiency and precision. A report from IndustryARC highlights that the global CNC plasma cutting machine market is projected to reach $5.8 billion by 2026, growing at a CAGR of 4.5%. This growth reflects the increasing demand for automated cutting solutions that offer both speed and accuracy. Among the most effective tools available for this purpose is the CNC plasma cutter, which significantly reduces operational costs while improving cut quality. By leveraging this innovative technology, businesses can streamline their production processes and maintain a competitive edge. As industries evolve, these machines are becoming indispensable for fabricators seeking to optimize their workflows and expand their capabilities.

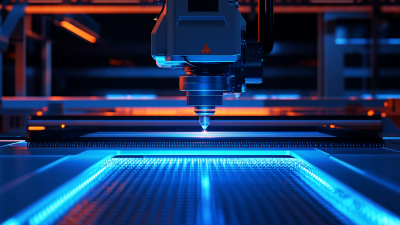

Benefits of Precision Cutting: Enhancing Product Quality with CNC Plasma Cutters

In today's competitive landscape, enhancing product quality is paramount, and this is where CNC plasma cutters shine. These machines offer unparalleled precision in cutting, allowing manufacturers to achieve intricate designs and tight tolerances that manual methods simply cannot match. The ability to automate the cutting process not only reduces the incidence of human error but also streamlines production, leading to faster turnaround times and cost savings. By investing in CNC plasma cutters, businesses can elevate their product standards, ensuring that each piece meets the exact specifications required in various applications, from automotive components to artistic metal designs.

Moreover, the integration of advanced technologies in CNC plasma cutting, such as Precision Hole Technology and SquareCut, represents a significant leap forward. These innovations enable manufacturers to produce complex shapes and features with ease, allowing for a more sophisticated and versatile approach to fabrication. As industries, including garment and construction, increasingly adopt these cutting-edge technologies, companies that utilize CNC plasma cutters will not only enhance their product offerings but also position themselves as leaders in their respective markets. The benefits of precision cutting extend far beyond improved aesthetics; they include increased efficiency and a stronger competitive edge in a rapidly evolving manufacturing environment.

Cost Efficiency Over Time: How CNC Plasma Cutters Save Money for Your Business

Investing in a CNC plasma cutter is a strategic move that can lead to substantial cost savings for businesses over time. One of the key advantages is the ability to minimize material wastage through the use of automatic nesting software. According to industry reports, businesses that implement automated nesting can reduce scrap material by up to 30%, significantly lowering overall operational costs. This software optimizes the layout of cuts, ensuring that every inch of material is utilized efficiently, which is crucial in industries where material costs can skyrocket.

Furthermore, the durability and precision of CNC plasma cutters contribute to long-term savings. Skilled operators can achieve cutting accuracy within +/- 0.1mm, which reduces the need for rework and scrap due to inaccuracies. A study indicated that companies employing CNC technology experience a decrease in labor costs by approximately 15%, as automated systems streamline production processes and minimize human error. Therefore, investing in a CNC plasma cutter not only enhances efficiency but also translates into a more favorable bottom line over the life of the equipment.

5 Compelling Reasons to Invest in a CNC Plasma Cutter for Your Business - Cost Efficiency Over Time

| Reason | Description | Cost Saving Potential (%) | Long-term ROI (Years) |

|---|---|---|---|

| High Precision Cutting | CNC plasma cutters achieve cleaner, more accurate cuts, reducing material waste. | 15% | 2 |

| Increased Production Speed | Faster cutting speeds lead to higher throughput in production cycles. | 20% | 1.5 |

| Versatility | Able to cut various materials and thicknesses, reducing the need for multiple machines. | 10% | 2.5 |

| Reduction in Labor Costs | Automation reduces the need for skilled labor on manual cutting tasks. | 25% | 2 |

| Lower Maintenance Costs | CNC plasma cutters typically require less maintenance compared to other cutting methods. | 5% | 3 |

Versatility in Applications: Expanding Your Service Offerings with CNC Technology

Investing in a CNC plasma cutter can significantly enhance the versatility of your business operations. CNC technology allows for precise and intricate cutting, enabling you to tackle a diverse range of materials—from metals like steel and aluminum to non-ferrous materials. This flexibility opens up opportunities for expanded service offerings, making your business a one-stop-shop for clients seeking high-quality fabrications, custom designs, and prototypes.

Moreover, the ability to easily switch between different projects means you can quickly adapt to market demands. Whether it’s creating signage, architectural components, or custom machinery parts, a CNC plasma cutter empowers you to meet various customer needs efficiently. As you embrace the versatility of CNC technology, your business not only increases productivity but also elevates its reputation in a competitive landscape, attracting clients who value quality and precision in their projects.

Boosting Production Speed: The Competitive Advantage of Fast CNC Plasma Cutting

Investing in a CNC plasma cutter can significantly enhance production speed, providing a crucial competitive advantage in today's fast-paced manufacturing landscape. CNC plasma cutting technology streamlines processes, allowing for precise and rapid cutting of materials. This not only improves efficiency but also reduces labor costs and minimizes material waste, positioning businesses to respond swiftly to market demands.

To maximize the benefits of a CNC plasma cutter, consider the following tips: First, invest in ongoing training for your operators. Well-trained staff can leverage the advanced capabilities of CNC machines to enhance production speed further. Second, regularly maintain your equipment to ensure optimal performance. Scheduled maintenance can prevent downtime and maintain cutting quality, ensuring that your production process remains efficient.

Additionally, integrate your CNC plasma cutter with advanced software solutions. This allows for better design and workflow management, enabling seamless transitions between different production stages. By leveraging technology in this way, businesses can capitalize fully on the speed and precision offered by CNC plasma cutting, securing a stronger foothold in the competitive industrial market.

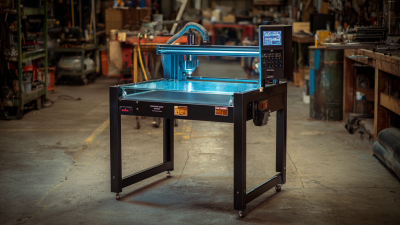

User-Friendly Technology: Simplifying Operations with Modern CNC Plasma Cutters

With the rapid advancement of technology, modern CNC plasma cutters have become a game-changer for many businesses. These user-friendly machines are designed to simplify operations, enabling companies to enhance their production efficiency and output quality. According to a report by MarketsandMarkets, the global CNC plasma cutting machine market is expected to reach $4.25 billion by 2025, underscoring the growing demand for these innovative tools in various industries.

One of the significant advantages of investing in a CNC plasma cutter is the ease of use. Many modern machines come with intuitive software that simplifies the design process, allowing operators to quickly transition from concept to cutting. This capability not only reduces training time but also minimizes errors that can occur during manual cutting processes. To maximize productivity, ensure proper maintenance of your CNC plasma cutter, including regular cleaning and system checks, which can extend the machine's lifespan and enhance its performance.

Furthermore, modern CNC plasma cutters offer advanced features such as automation and real-time monitoring, making operations even more straightforward. According to a study by Grand View Research, automation in manufacturing can lead to productivity improvements of up to 30%. Implementing such technology allows businesses to streamline workflows, ultimately driving profitability. For businesses looking to optimize their operations, investing in a CNC plasma cutter could be a pivotal step forward.

Benefits of Investing in CNC Plasma Cutters for Businesses

Related Posts

-

Essential Insights for Maximizing Efficiency with Cnc Plasma Cutters

-

How to Identify Top Quality Manufacturers for Small Plasma Tables in a Global Market

-

Revolutionizing Precision Cutting with Small Plasma Tables for Global Manufacturers

-

Discover Cutting Edge Innovations at the 137th Canton Fair for Cnc Steel Cutting Machine Buyers

-

7 Reasons Why the Best Small Plasma Table is a Game Changer for Your Business

-

China's Trusted Quality in Best Plasma Laser Cutters for Global Buyers