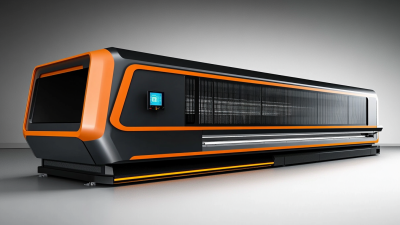

7 Essential Features You Must Know About Industrial Laser Cutting Machines

In the ever-evolving landscape of manufacturing, efficiency and precision are paramount, and the Industrial Laser Cutting Machine stands at the forefront of these advancements. This powerful tool utilizes focused laser beams to achieve intricate cuts and shapes in a variety of materials, offering unparalleled accuracy and minimal waste. As industries strive to enhance production processes while maintaining high-quality standards, understanding the essential features of these machines becomes crucial. In this guide, we will delve into seven key attributes that define the capabilities of Industrial Laser Cutting Machines, equipping you with the knowledge to make informed decisions for your business. Whether you are a seasoned professional or new to the world of laser cutting, recognizing these features will empower you to leverage this technology effectively and stay ahead in the competitive market.

Essential Understanding of Precision Tolerance in Laser Cutting Machines

When discussing industrial laser cutting machines, precision tolerance plays a critical role in achieving high-quality results. Understanding the concept of precision tolerance is essential for professionals working with these machines, as it directly impacts the quality of the cuts. Precision tolerance refers to the allowable limit of variation in dimensions, which ensures that the final product meets the required specifications. A small margin of error can be significant in industries such as aerospace or automotive, where even the slightest misalignment can lead to major failures.

To enhance precision tolerance in laser cutting, consider these tips: First, regularly calibrate your machine to maintain accuracy. This involves checking the alignment of the laser beam and ensuring all components are functioning correctly to achieve precise cuts. Second, select the appropriate laser settings for the material being cut. Different materials may require adjustments in speed, power, and focal length to maintain tolerance levels. Finally, conduct routine quality control checks on your finished products to identify any deviations early in the process, ensuring that any adjustments can be made promptly.

By focusing on precision tolerance, operators can significantly increase the efficiency and effectiveness of industrial laser cutting machines, resulting in higher-quality outputs that meet demanding industry standards.

The Role of Power and Speed Settings in Optimizing Cutting Efficiency

When it comes to industrial laser cutting machines, understanding the role of power and speed settings is crucial for optimizing cutting efficiency. The balance between these two parameters significantly impacts the quality of the cut and the overall operational costs. According to a report by TechSci Research, the global laser cutting machine market is expected to grow at a CAGR of 5.5% between 2020 and 2025, indicating the increasing reliance on precision cutting technology in industries such as automotive and aerospace.

Power settings determine the intensity of the laser beam, with higher power leading to deeper cuts and faster processing times. However, excessive power can cause material burn and deformation. For example, a study by the International Journal of Advanced Manufacturing Technology noted that optimizing power settings can reduce material waste by up to 30%. On the other hand, speed settings dictate how quickly the laser moves across the material, influencing edge quality and finishing. Striking the right balance between speed and power can enhance productivity while maintaining high-quality cuts, making it imperative for operators to understand and adjust these settings based on material and application requirements.

Material Compatibility: How Different Materials Affect Laser Cutting Performance

When considering industrial laser cutting machines, material compatibility is a crucial aspect that directly influences cutting performance. Different materials interact uniquely with laser technology, impacting the quality and speed of the cut. For instance, metals like stainless steel and aluminum typically require higher power settings compared to plastics or wood, with laser cutting speeds varying accordingly. Recent industry reports indicate that fiber lasers can cut materials like mild steel up to 25mm thick with precision, achieving speeds of up to 30 meters per minute. In contrast, acrylic may be processed at a much faster rate due to its lower density and thermal conductivity.

Tip: Always conduct preliminary tests on new materials to fine-tune your laser settings for optimal results. Experimenting with varying speeds and power levels can help you determine the best combination for each material type.

Materials like ceramics and composites present unique challenges as well, often necessitating specialized laser systems. Ceramics, for example, are brittle and require careful handling to avoid fractures during cutting. A recent analysis showed that using a pulsed laser rather than a continuous wave can significantly reduce the risk of damage while cutting tough materials.

Tip: Invest in a good cooling system for your laser cutter, especially when working with materials that generate high heat during the cutting process. This not only prolongs the life of the cutting machine but also ensures cleaner cuts by managing heat levels effectively.

The Importance of Automation and Software Integration in Modern Machines

In today's rapidly evolving manufacturing landscape, the integration of automation and software into industrial laser cutting machines has become a game-changer. These advanced technologies not only enhance efficiency but also streamline operations, ensuring precision and consistency in the cutting process. Automation minimizes manual intervention, significantly reducing the risk of human error, while sophisticated software allows for real-time monitoring and adjustments, optimizing productivity and material usage.

Tip: When selecting a laser cutting machine, consider one that offers advanced software features, such as customizable cutting parameters and remote access capabilities. This can save time and increase flexibility on the production floor.

Moreover, the synergy between automation and software can facilitate greater data collection and analysis. By implementing machine learning algorithms, companies can predict maintenance needs and identify performance bottlenecks, leading to proactive solutions that keep production lines operating smoothly.

Tip: Invest in training for your staff on the latest software tools and automation techniques. This enhances their skill set and empowers your team to leverage the full potential of modern laser cutting technologies.

Maintenance and Longevity: Key Factors to Ensure Optimal Machine Performance

When it comes to ensuring the optimal performance of industrial laser cutting machines, maintenance and longevity are crucial factors. Regular maintenance not only prolongs the life of the machine but also enhances its efficiency, allowing for precise cutting operations. Implementing a structured maintenance schedule can help detect potential issues before they escalate into costly repairs.

Tips for maintaining your laser cutting machine include regularly checking the alignment and focus of the laser beam. Ensure that mirrors and lenses are clean, as any dust or debris can affect the cutting accuracy. Additionally, inspect the cooling system to prevent overheating, which can impair performance and lead to significant downtimes.

Another important aspect is to keep software and firmware up to date, as this ensures that the machine operates with the latest features and security patches. Training operators on best practices during use can also minimize wear and tear, thus extending the machine's operational life. By prioritizing these maintenance tasks, you can maximize the efficiency and longevity of your laser cutting equipment.

7 Essential Features You Must Know About Industrial Laser Cutting Machines - Maintenance and Longevity: Key Factors to Ensure Optimal Machine Performance

| Feature | Description | Importance | Maintenance Tips |

|---|---|---|---|

| Cutting Accuracy | Precision of the laser beam to ensure detailed cuts | Critical for achieving high-quality output | Regular calibration and focusing checks |

| Material Compatibility | Ability to cut a variety of materials | Versatility in processing different projects | Test different materials and adjust settings accordingly |

| Cutting Speed | Rate at which the laser can cut through materials | Directly affects production efficiency | Monitor performance and clean components regularly |

| Cooling System | Maintains optimal temperatures during operations | Prevents overheating and extends equipment life | Inspect and clean cooling units frequently |

| Safety Features | Includes sensors, barricades, and emergency stops | Ensures operator safety during machine operations | Conduct regular safety audits and training |

| User Interface | Intuitive controls and software for operation | Affects ease of use and training time | Keep software updated and provide training sessions |

| Longevity Features | Design elements that promote durability | Reduces long-term maintenance costs | Follow the manufacturer’s guidelines for upgrades |

Related Posts

-

Top 10 Industrial Laser Cutting Machine Manufacturers from China at the 137th Canton Fair

-

Unveiling the Future of Best Small CNC Machines Market Analysis and Real World Applications by 2025

-

Unlocking Precision with Cnc Tools Essential Specifications and Best Practices for Global Buyers

-

Driving Success with Plate Laser Cutting Machine at the Record Breaking Canton Fair 2025

-

The Evolution of Cnc Drilling Machines in Global Manufacturing Trends

-

Unlocking the Secrets to Finding the Best Cnc Machine Suppliers for Your Business Needs