Mastering Your Cnc Plasma Cutter A Comprehensive Guide for Beginners

In the fast-evolving landscape of metal fabrication, mastering your CNC plasma cutter has become essential for both hobbyists and professionals alike. According to a recent industry report, the global CNC plasma cutting market is projected to reach $5.26 billion by 2027, growing at a CAGR of 4.8%. This growth underscores the increasing demand for precision cutting technology that allows for flexibility, efficiency, and high-quality results. For beginners venturing into this realm, understanding the intricacies of operating a CNC plasma cutter is vital for achieving desired outcomes and maximizing productivity. This comprehensive guide will equip you with the essential knowledge and skills needed to navigate the world of CNC plasma cutting, ensuring that you optimize this powerful tool to its fullest potential.

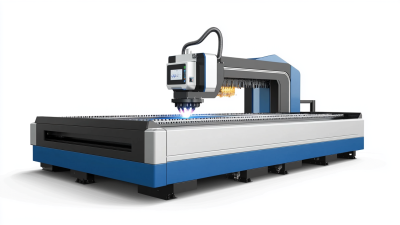

Understanding the Basics of CNC Plasma Cutting Technology

CNC plasma cutting technology has revolutionized the fabrication industry, offering speed and precision in metal cutting. At its core, this process utilizes an electric arc to create plasma, which is then directed through a narrow nozzle to cut through various materials, including steel, aluminum, and brass. Understanding the basic components of a CNC plasma cutter, such as the power supply, torch, and computer software, is essential for beginners aiming to master this technology.

CNC plasma cutting technology has revolutionized the fabrication industry, offering speed and precision in metal cutting. At its core, this process utilizes an electric arc to create plasma, which is then directed through a narrow nozzle to cut through various materials, including steel, aluminum, and brass. Understanding the basic components of a CNC plasma cutter, such as the power supply, torch, and computer software, is essential for beginners aiming to master this technology.

Tips: Start by familiarizing yourself with the operation settings of your CNC plasma cutter. Adjust parameters like cutting speed and amperage based on the material thickness to enhance cutting efficiency and quality. Additionally, invest time in learning the software interface, as it plays a crucial role in designing and executing cutting paths accurately.

As you gain confidence, experiment with different materials and thicknesses. Keep a log of settings and outcomes to refine your techniques. Consistent practice will not only improve your skills but also deepen your understanding of CNC plasma cutting dynamics, setting you on the path toward mastery.

Exploring the Advantages of Using CNC Plasma Cutters in Metalworking

CNC plasma cutters have revolutionized the metalworking industry by offering precision and efficiency that traditional cutting methods cannot match. According to a report by the Markets and Markets Research, the global CNC plasma cutting machines market is expected to reach $7.23 billion by 2026, growing at a CAGR of 5.6%. This surge emphasizes the increasing demand for high-quality metal fabrication and the advantages that CNC plasma technology brings to the table, such as faster cutting speeds and less material waste.

One significant advantage of CNC plasma cutters is their versatility. They can effortlessly cut through various materials, including steel, aluminum, and brass, while delivering consistent results. Additionally, with advancements in technology, these machines can be equipped with smart features that enhance efficiency and reduce operational costs. As noted by the Fabricators & Manufacturers Association, companies that utilize CNC plasma cutting report up to a 30% increase in production efficiency compared to traditional methods.

Tip: When getting started with a CNC plasma cutter, consider investing in proper training and resources. Understanding the software and the machine’s capabilities can significantly reduce the learning curve.

Another tip is to regularly maintain your equipment. Keep the torch and consumables clean and in good condition to ensure optimal performance and longevity of your CNC plasma cutter. Regular checks can prevent costly breakdowns and keep production flowing smoothly.

Mastering Your CNC Plasma Cutter: A Comprehensive Guide for Beginners

| Aspect | Details |

|---|---|

| Definition | CNC plasma cutting is a process that uses a plasma torch to cut through electrically conductive materials. |

| Materials | Common materials include steel, stainless steel, aluminum, brass, and copper. |

| Advantages | High cutting speed, versatility, clean edges, minimal waste, and ability to cut complex shapes. |

| Applications | Used in manufacturing, automotive, aerospace, and metal art fabrication. |

| Safety Precautions | Use protective gear, ensure proper ventilation, and follow equipment safety guidelines. |

| Learning Resources | Online tutorials, community forums, and local workshops for hands-on practice. |

Key Features That Enhance Efficiency in CNC Plasma Cutting

In the rapidly evolving landscape of CNC plasma cutting, understanding the key features that enhance efficiency is vital for beginners looking to master this technology. A significant aspect of these machines is their automation capabilities, which not only streamline operations but also increase precision. Automated CNC plasma cutters integrate advanced software solutions that facilitate faster programming and improved nesting processes. This results in optimal material usage and reduced waste, which is crucial in competitive manufacturing environments.

Another essential feature is the adaptability of CNC plasma cutting machines to various applications, from industrial settings to intricate projects in the garment industry. The introduction of AI and smart technologies has further revolutionized equipment performance. By incorporating sensors and data analytics, these machines can fine-tune their operations in real-time, ensuring superior cuts and finishing quality. As the market for CNC plasma cutting machines is projected to grow significantly, beginners should focus on these features to enhance their skills and maximize efficiency in their cutting practices.

How CNC Plasma Cutters Increase Precision and Quality in Fabrication

CNC plasma cutters have revolutionized the fabrication industry, providing an unmatched level of precision and quality. Unlike traditional cutting methods, these advanced machines utilize a high-velocity jet of ionized gas, or plasma, to effortlessly slice through a variety of materials, including steel, aluminum, and copper. This technology allows for remarkably intricate designs to be created with consistent accuracy, which is essential for industries that demand meticulous attention to detail.

The integration of CNC technology enhances this precision even further. By leveraging computer-controlled operations, users can execute complex shapes and patterns that would be nearly impossible to achieve with manual cutting techniques. This automated process not only improves the consistency of the cuts but also significantly reduces material wastage. As a result, businesses can maintain higher quality standards while also optimizing their production processes, leading to increased efficiency and cost-effectiveness in their fabrication projects.

Cost-Effectiveness: Why CNC Plasma Cutters are Worth the Investment

CNC plasma cutters have become a game-changer in the metal fabrication industry, offering unparalleled precision and efficiency. One of the primary reasons for their growing popularity is their cost-effectiveness. While the initial investment might seem significant, the long-term savings in labor costs and material waste are substantial. As industries move towards automation, leveraging CNC technology not only reduces physical labor but also enhances overall productivity.

The market for plasma cutting machines is projected to grow significantly due to the increasing demand for automated industrial processes. By automating cutting operations, businesses can achieve consistent results, minimize errors, and expedite production timelines. Furthermore, the shift towards CNC plasma cutters means that companies are better equipped to handle complex designs and larger volumes of work without sacrificing quality. In essence, investing in a CNC plasma cutter is not merely acquiring a tool, but embracing a future where efficiency and precision drive profitability.

Cost-Effectiveness of CNC Plasma Cutters

This chart illustrates the cost-effectiveness of CNC plasma cutters compared to traditional cutting methods. The initial investment and operational costs are highlighted, along with maintenance costs, output quality, and time efficiency, providing a comprehensive overview of the advantages of CNC plasma cutters for beginners considering their investment.

Related Posts

-

Finding Reliable Suppliers for CNC Plasma Cutting Machines A Comprehensive Guide

-

How to Identify Top Quality Manufacturers for Small Plasma Tables in a Global Market

-

Unlocking Precision with Cnc Tools Essential Specifications and Best Practices for Global Buyers

-

Essential Insights for Maximizing Efficiency with Cnc Plasma Cutters

-

Discover Cutting Edge Innovations at the 137th Canton Fair for Cnc Steel Cutting Machine Buyers

-

5 Compelling Reasons to Invest in a Cnc Plasma Cutter for Your Business