Ultimate Comparison: Discover the Top 5 Best Plasma Laser Cutters for Global Buyers

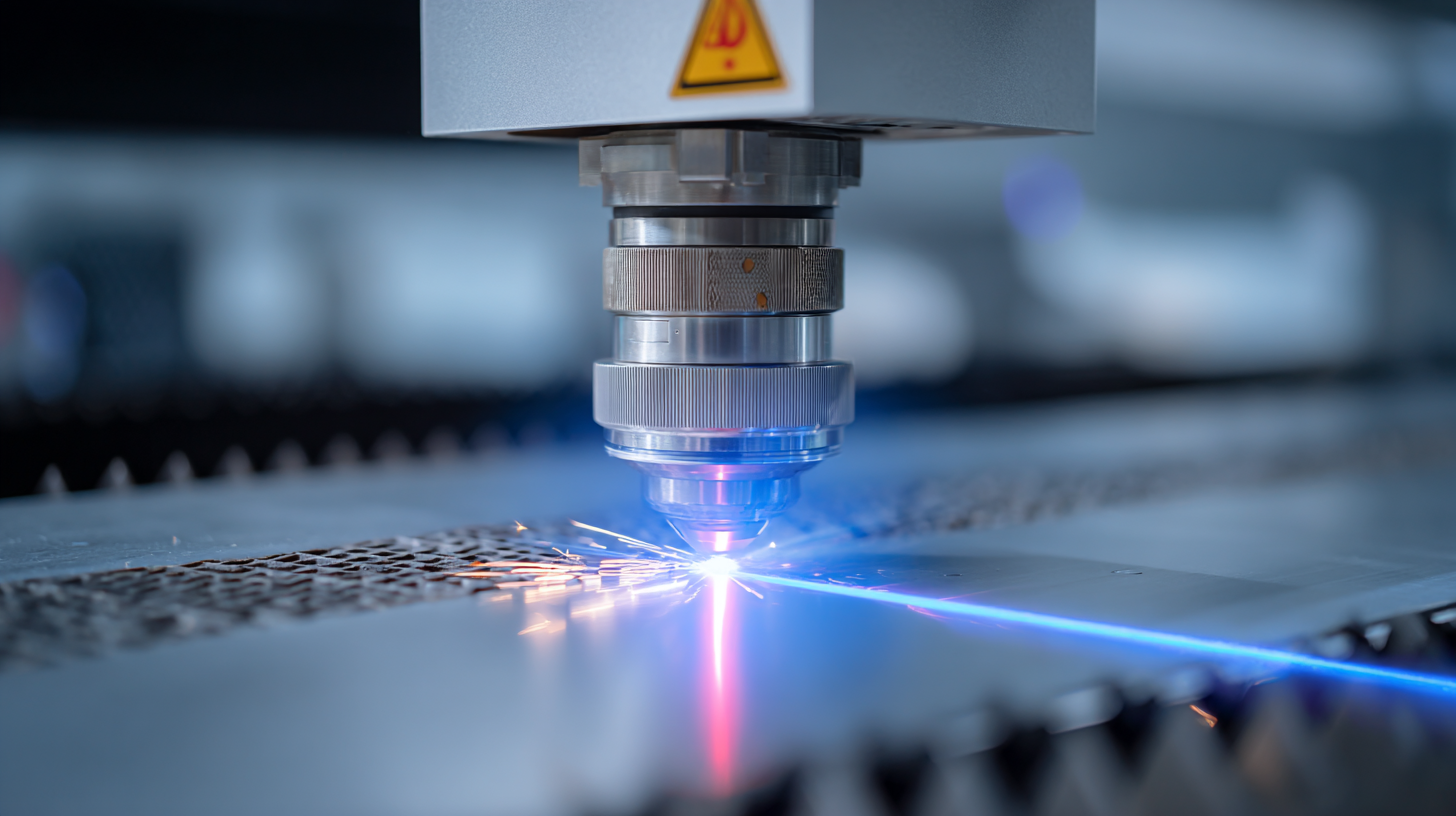

The machining industry is witnessing an unprecedented evolution as we move towards 2025, marked by significant advancements in technology that redefine efficiency and precision. Among these innovations, the Plasma Laser Cutter stands out as a transformative tool, merging the strengths of both plasma cutting and laser technology to deliver unparalleled results.

As global buyers seek to enhance their production capabilities, understanding the top options in the market becomes essential. In this ultimate comparison, we will delve into the five best Plasma Laser Cutters recognized for their performance, reliability, and versatility. By examining these cutting-edge machines, we aim to guide buyers in making informed decisions that align with the future trends of the industry, ensuring they are well-equipped to face the challenges and opportunities of advanced manufacturing.

Factors to Consider When Choosing a High-Quality Plasma Laser Cutter Manufacturer

When selecting a high-quality plasma laser cutter manufacturer, several factors should be taken into account to ensure you make the right investment. Firstly, you should assess the manufacturer’s reputation and experience in the industry. Look for companies that have a proven track record in producing reliable and innovative cutting technologies. Customer reviews and testimonials can provide valuable insights into the manufacturer's reliability and performance.

Additionally, consider the technical specifications of the plasma laser cutters offered. Evaluate the cutting speed, precision, and overall efficiency of the machines. A model that meets your production requirements will ultimately enhance your operational capabilities. It's also beneficial to examine the warranty and support services provided, as these can greatly impact your long-term satisfaction with the product.

**Tips:**

1. Prioritize manufacturers that offer training and support for their equipment, ensuring you and your team can utilize the technology effectively.

2. Compare the energy consumption of different models, as lower operational costs can be a significant factor in your overall budget.

3. Keep an eye on emerging technologies in plasma cutting to ensure you're investing in the most up-to-date equipment, which can improve efficiency and reduce waste.

Ultimate Comparison of Plasma Laser Cutters

Top 5 Plasma Laser Cutters: Features, Specifications, and Performance Comparison

When it comes to cutting materials with precision and efficiency, plasma laser cutters have revolutionized the industry. In our ultimate comparison of the top five plasma laser cutters, we delve into their features, specifications, and performance to help global buyers make informed decisions. These advanced machines are equipped with automatic nesting software, which not only reduces costs but also minimizes material wastage. Intelligent features enable users to optimize their cutting processes, ensuring that every job is done with the utmost accuracy.

Each of the plasma laser cutters highlighted showcases unique capabilities tailored to different applications, from industrial layouts to artistic designs. With cutting speeds and power levels available at various ranges, buyers can find a model that meets their specific requirements. The performance comparison of these top picks will reveal which machines stand out in terms of reliability, ease of use, and overall effectiveness in a competitive market, making it easier for buyers to select the right tool for their needs.

Insights into Customer Reviews and Satisfaction for Leading Plasma Laser Cutters

When it comes to selecting the best plasma laser cutter, customer reviews and satisfaction ratings can play a pivotal role in decision-making for global buyers. Analyzing feedback from users of leading models, it’s clear that factors such as precision, cutting speed, and ease of use heavily influence overall satisfaction. For instance, many buyers highlight the exceptional accuracy of the Hypertherm Powermax series, pairing state-of-the-art technology with user-friendly interfaces that make for a seamless cutting experience.

Additionally, buyers often compare the durability and reliability of plasma laser cutters. Models from brands like Esab and Lincoln Electric receive positive remarks not only for their cutting performance but also for their robust build quality. Customers have shared that these machines withstand intense usage in demanding environments, further solidifying their value. Furthermore, support services and warranty offerings are significant in crafting customer loyalty, with many users appreciating brands that provide comprehensive after-sales support. The aggregation of such insights reveals a clear trend: top-rated plasma laser cutters are those that combine advanced features with dependable customer service, catering to the needs of users across various industries.

Ultimate Comparison: Discover the Top 5 Best Plasma Laser Cutters for Global Buyers

| Model | Cutting Thickness (mm) | Max Cutting Speed (mm/min) | Power Consumption (KW) | Customer Satisfaction (%) |

|---|---|---|---|---|

| Model A | 25 | 5000 | 10 | 92 |

| Model B | 30 | 4500 | 12 | 89 |

| Model C | 20 | 6000 | 9 | 94 |

| Model D | 35 | 4000 | 15 | 85 |

| Model E | 40 | 3000 | 20 | 80 |

Understanding the Benefits of Investing in Premium Plasma Laser Cutting Technology

Investing in premium plasma laser cutting technology offers numerous benefits that can significantly enhance productivity and precision in various creative projects. As industries evolve, the demand for advanced cutting solutions has grown, and plasma cutting technology has emerged as a front-runner due to its ability to cut through thick materials with remarkable speed and accuracy. With the latest innovations, plasma cutters are not only efficient but also capable of handling diverse materials, providing versatility for both industrial applications and artistic endeavors.

China is rapidly becoming a leader in advanced manufacturing, showcasing impressive innovation abilities within its universities and companies. This surge in technological advancements aligns perfectly with the rising popularity of high-quality plasma laser cutters, which facilitate the creation of intricate designs and complex shapes. By opting for superior cutting technology, global buyers can ensure they are at the forefront of industry developments, enhancing their competitive edge while exploring limitless creative possibilities in their projects.

Key Industry Trends Influencing Plasma Laser Cutter Selection for Global Buyers

As the market for plasma laser cutters evolves, several key industry trends are significantly influencing buyers' decisions worldwide. One prominent trend is the increasing demand for precision and efficiency in cutting processes. Global buyers are now prioritizing equipment that can deliver high-quality results while minimizing material waste. This shift has led manufacturers to innovate and incorporate advanced technologies that enhance cutting accuracy and speed.

When selecting a plasma laser cutter, it's essential to assess your specific needs and operational requirements. **Tip: Consider the materials you will be working with and the thickness ranges the cutter needs to accommodate.** Not all cutters are created equal, and understanding your unique application will help in choosing the most suitable model for your business.

Another crucial trend is the emphasis on energy efficiency and sustainability. As industries strive to reduce their carbon footprint, buyers are seeking machines that not only perform well but also consume less power. **Tip: Look for models that offer features such as inverter technology or optimized power consumption to ensure the long-term sustainability of your cutting operations.** By keeping these trends in mind, global buyers are better equipped to make informed decisions and invest in plasma laser cutters that align with their strategic goals.